Blog

Types of glass personalisation explained

Wondering how to customise your printed glassware? Want to know your printing options? We have prepared this guide so you can make the right choice when planning to promote your brand on glasses.

Silkscreen printing

This is a proven printing process in which the colours get printed through a fine-meshed fabric with a rubber squeegee. Each colour gets printed with its own stencil and thus in high-quality full tones. For direct printing and decal decoration, high-quality colour systems get used. The ceramic decoration requires a firing process in which the colours melt with the surface. Depending on the material, temperatures during firing will reach between 580 to 1000 degrees Celsius. Organic colours offer brilliant shades and are free of heavy metals. Up to eight colours can be applied to each glass. These colours get applied to the item by UV light and special heat treatment. This innovative colour system can even decorate toughened safety glass. It’s particularly cost-effective for large print runs.

Embossed Print

One of the latest technological innovations in the promotional glassware industry is embossed printing. This exceptional decoration method not only looks impressive but also feels unique, allowing branded glassware to achieve an effect that was previously only available to those ordering completely bespoke glassware with custom-made moulds—making it a very costly option.

Not anymore! A specialised printer creates a stunning result by printing layer upon layer until the artwork stands out in relief. Embossed printing is also available in colour, as pigments are mixed into the transparent acrylic used in the printing process.

There is, however, one caveat: if pubs use aggressive renovator solutions in their dishwashers, this may affect the longevity of the decoration. Otherwise, it is a superb option to make your glassware truly stand out!

Decals

Decal is the method used for special printing requirements. Typical examples are photo-realistic logos, complex geometrical shapes and handle decorations. Other examples include decoration over edges, full-surface decorations or small multicoloured batches. The Decal process to the glass print is hand applied. Decals will print similarly to your colour specifications or as a four-colour printing (CMYK) as part of a gang sheet process.

Halftone Printing

Halftone is the reprographic technique that simulates continuous tone imagery using dots. These dots vary either in size or in spacing, thus generating a gradient-like effect. Halftone can also refer to the image that gets produced by this process.

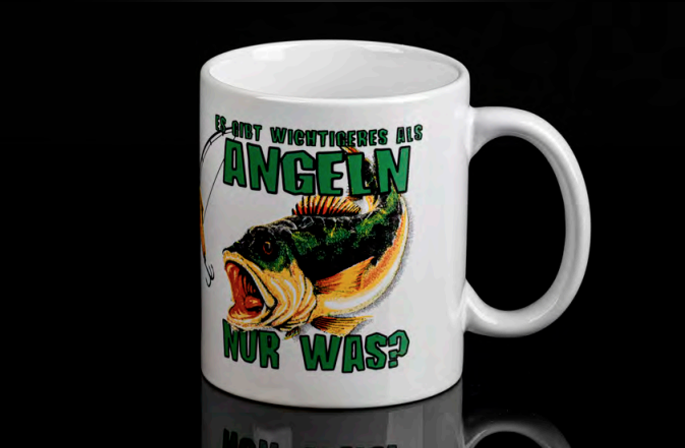

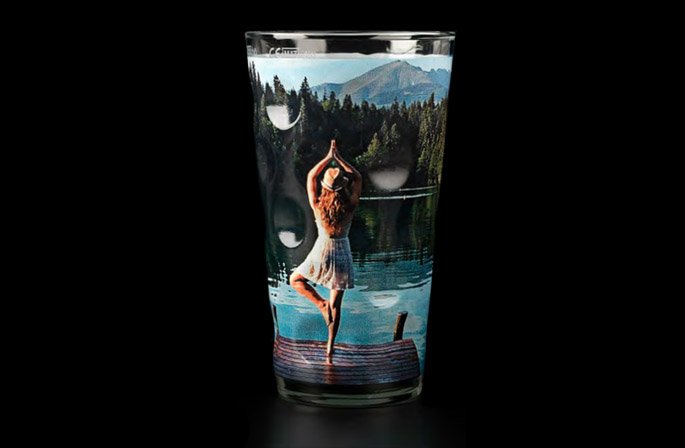

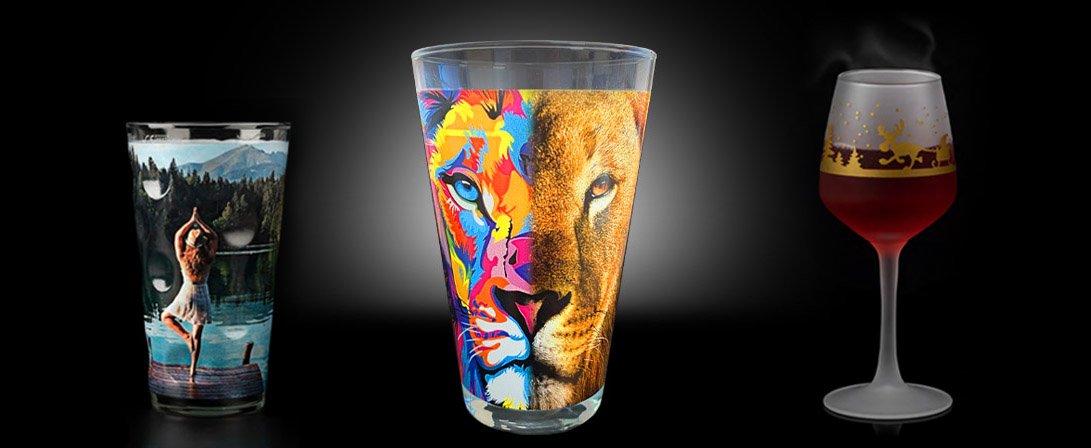

Flexi Print

Flexi Print is a digital printing process suitable for almost all types of glasses. The method offers colourful, detailed and high-quality printing and an extended decoration area. Flexi print is suitable for Photorealistic motifs and personalisations. Small production runs are possible at manageable initial costs.

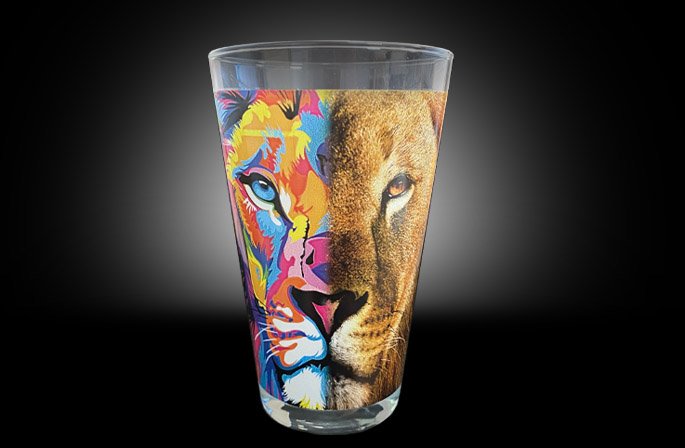

Premium Print

A transfer ribbon gets used to apply a four-colour print. Ideal for photorealistic images with high colour and contrast. Available in glossy and matt finishes.

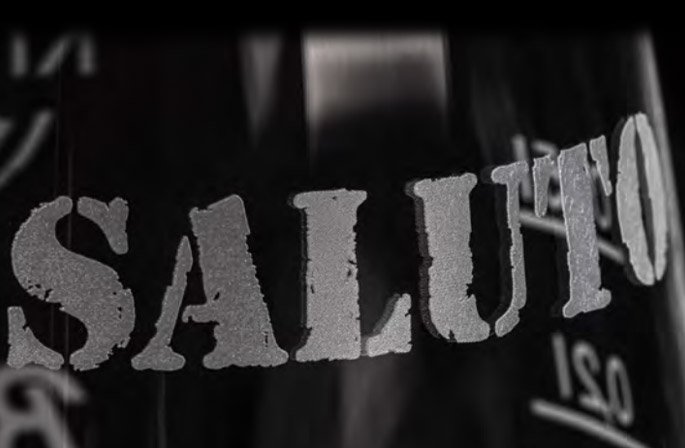

Etched white

This process offers a cheaper alternative to engraving. Since it is a direct print, your logo will still have a homogenous print image with high-edge definition. Etched white can get combined with other print methods and it’s ideal for small print runs.

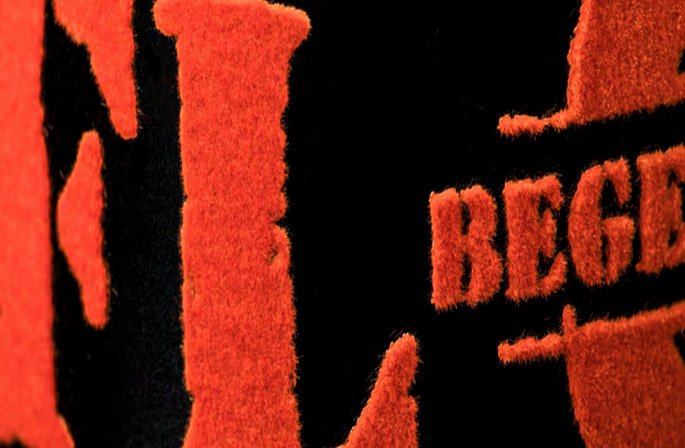

Flock Print

Your logo will stand out through the use of high-quality, velvety soft flock fibres. Flock Print can get implemented in one colour and with a minimum line thickness of 2 to 3 mm. Multicoloured decorations in combination with silkscreen-direct-printing are also possible.

Glassware Coating

Glassware

A unique and budget-friendly decoration method is called glassware coating. Each glass is delicately sprayed with a water-based colour, creating a stunning and attention-grabbing effect. Whether you opt for full or partial spraying, they are sure to be noticed. Our coated glasses and decoration methods are fully compliant with EU regulations and can be safely used in the dishwasher.

Galaxy

This special coating technique is possible on glass articles. The inside shines in radiant silver and the outside can get coated with a colour of your choice. Additionally, the glass can get imprinted inside or outside.

Satin Finish

By using a special surface treatment, glasses can obtain a milky/mat/frosted appearance. It is absolutely dishwasher safe and the satin finish can get combined with other decoration methods.

Glossy

This method which uses frosted glass creates a discreet and distinguished look. By removing the satin finish at the desired areas, your logo appears in clear glass. Glossy can be combined with other printing processes.

Sparking Point

Enhancing the optical impression of champagne by drilling a ‘sparkling point’, this method makes bubbly and other fizzy drinks appear to sparkle stronger and longer. It is a little known secret that this method is often used when ordering promotional Champagne flutes.

In the beer industry, this process is known as nucleation. We have written an in-depth article explaining what it is and how it works.

Precious Metal

Real gold or silver can be printed. In one colour or in combination with other ceramic colours. Compared with the standard colour range, precious metals are only partially dishwasher proof.

Metallic

This is a substitute for Precious Metals. It is much cheaper and has good dishwasher resistance.

Painty

Children will love this type of branding because they can paint your logo or image with coloured pens. We recommend printing the surface in white or etched to achieve the necessary contrast for the pens. Wash off the colours and paint the glass all over again!

Milky

Milk or other juices can be a part of your logo by changing the colour of the background when poured into the glass. White areas are lithographically omitted so that the entire logo becomes visible when the drink gets poured into the glass.

Window Effect

This is a clever method. When a liquid is poured into the glass, the printing will appear larger while creating a 3D effect

Toughened Glass For Hot Drinks

Drinking glassware and glass cups can have a thermal treatment applied to them. This treatment achieves a robust finish so the glasses can withstand heat and are suitable for hot drinks. One or multi colours are available.

Glass Metalization Effect

Metals have long been used to give glassware a distinctive look. Gold and silver is used to create luxurious glassware. This process is used to sublimate a bottle by giving it a metalized aspect and a mirror effect. It is produced by applying thin layers of metal, until the full or partial surface of the bottle is covered, which allows you to play with opacity or transparency effects. Metal plating is a popular way to add an extra level of sophistication to glassware, and can be used to create unique and stylish designs.

Illuminated Circles Effect

Do you know what type of printing or glass finish you want? Browse all glassware or contact our team for advice.